50 HP Variable Speed Drive Specs:

* 235 SCFM @ 100 PSI - 220 SCFM @ 115 PSI - 200 SCFM @ 145 PSI

In high and low demand applications, this can save you up to 33% on your electric bill

Available in 208/220/460 Voltage

The Benefits of VSD DRIVE and of our German Rotary screw pump is 24 hours/7 days/week operation at 100% duty cycle for 70,000-100,00 hours use depending on the pressure the unit is set at - the lower the pressure the longer the pump life and less bearing wear.

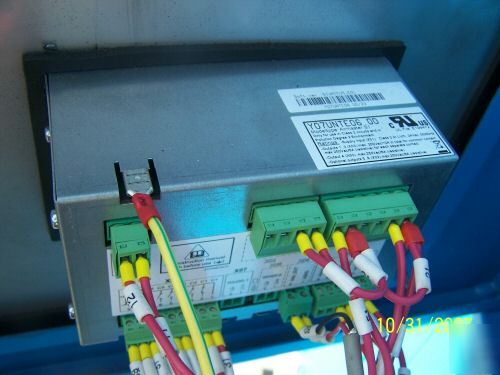

This unit is Eaton Compressor’s newest and latest technology in a rotary screw compressor for the compressed air industry. This rotary screw machine gives you a HUGE ENERGY SAVINGS on your electric bill. This unit has the same proven years of Premium Quality in our Rotary Screw air compressor, but now has added a Variable Speed Frequency Drive. This unit has name brand Telemacanique electrical components. The variable speed unit changes the Frequency from 60 cycles down to 18 cycles. The electricity coming into your home and business is 60 cycles. This electric motor has a frequency up to 60 cycles or 60HZ - both mean the same thing.

When 60 cycles of electricity are inducted into this electric motor, the motor RPM is a low 1750. However, the Variable Speed Inverter Drive will change the 60HZ or 60 cycles of electricity from 60 cycles down to 18 cycles, depending on the pressure. The whole idea of energy savings with this unit is the lower the cycles, the lower the amp draw coming from your electric motor. The electricity amp draw that an electric motor is using determines what your electric bill is. The lower the amp draw that your electric motor is using, the lower your electric bill will be!!

If you are running a high air demands all day long and not low air demands of air, the benefits of the Variable Speed Drive will not save you much and the higher cost of the variable drive machine over a regular drive machine without the variable speed capabilities will not benefit you. The reason for this is if you are running the machine 70% to 100 % load all day long under heavy air usage the electric motor is running around full speed of 1750 motor RPM and not using much of the lower motor RPM and lower amp draw benefits.

The other and most definite savings on the Variable Speed Drive Machine is your motor bearings will have less wear with lower RPM—your belts will have less wear with lower RPM- and most of all, you will get an even longer rotary screw pump life with lower RPM.

This unit does not have Y Delta Starting like our regular drive units. So the Starting Benefits of this machine are even better than Y/Delta starting it starts from the Variable Speed Inverter Drive. This machine will start at 18 cycles with only 33% of the full load amps and only 530 RPMs and will maintain the low amp starting for about 12 seconds after the machines starts. After the 12 seconds under start up the unit will then start increasing the motor speed and CFM capacity. This Variable Speed Drive unit also starts just like our regular drive unit because it is on a 12 second time delay, so there is no load on the unit under start-up mode. Both no load start up combined with 18 cycle starting is another huge advantage you will gain on your electric savings.

The PLC controller/computer gives you a wide range of advantages to control and operate your machine efficiently without worry. The PLC gives you a maintenance parameter that you can easily view at any time during the compressor operation. You can view your hours on the machine and also view the set list of hours that are put on the oil and filters for service and maintenance. We set these machines up with a set amount of time you can put in the synthetic oil – oil/separator filter – air filter – and spin-on oil filter. So when you go to the maintenance schedule you can view the hours on each maintenance item. For example if your oil has 1530 hours on it and the maximum hours is set for 4000 for changing, you can view each maintenance item and know how much time there is before you need to change that maintenance item. After you change the maintenance item - oil filters etc., then you can set the time back to 0 and it will keep track of that maintenance item all over again. It you would lose track of changing these maintenance items, this machine has a built in alarm to warn you what needs to be changed listed on the computer screen.

The PLC will run under voltages + 15% and -10%. If the voltage is too low, the unit will shut down and if the unit is too high, the unit will shut down. The PLC also has a adjustable amp range and will protect your electric motor from too high of an amperage – this unit will shut down protecting the electric motor from any high amp draw. This unit is also protected incase you might drop a phase – with a fuse system if you would drop a fuse - the PLC will sense this and shut down the compressor within 5 seconds after phase failure.

This PLC also has a list of amperage for each leg of the 3 phase which you can view as the unit is running. This is nice to keep track on how your electric motor is performing as it is running.

This PLC will also keep track if it should over pressure-the unit will shut down on over pressure safety.

This PLC also has a adjustable range of time from 5 minutes to 20 minutes so when the unit is running under no load it will turn off and then automatically restart when the pressure gets to the low set point on the PSI. This will save you energy so when the compressor is not being used you are not wasting electricity.

This PLC will also keep track of the total run hours. It will keep track of the time the unit is pumping under load and the time under no load. This makes it nice to keep track of your percentage of full load pump time.

This PLC also keeps track of the day month year and time.

The PLC will shut down the unit if it gets high in air temperature or if the unit runs low in oil.

The PLC will also sense if the unit is wired for the wrong rotation and it will not allow the unit to run.

This PLC also has a fault history that stores if the unit shuts down of why it shut down and makes it easy for any trouble shooting problems.