Welcome to DRO PROS. We are a FAGOR USA authorized dealer of digital readout equipment.

- It is designed to fit a Milling Machine with an X travel of 32", a Y travel of 16", and a Z travel of 16" -

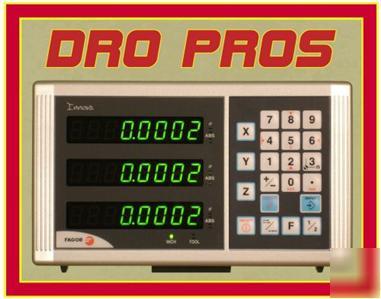

The FAGOR Innova 30i-M is the latest and most powerful display offered by Fagor, and DRO PROS has it!

Click twice and hold down your mouse button to rotate our 3D display: FAGOR three axis 16" x 32" x 16" travel EXTREME 3K Milling Machine kit:

The EXTREME 3K kit comes complete with the following:

Innova 30i-M three axis display

X Axis Scale: MKT-82 0.0002" resolution scale (overall travel 32.28", length 36.48")

Y Axis Scale: MKT-42 0.0002" resolution scale (overall travel 16.54", length 20.74")

Z Axis Scale: CT-42 0.0002" resolution scale (overall travel 16.54", length 20.74")

"Mill L" Bracket Kit to mount both X and Y scales

"Adj L" Bracket Kit to mount Z scaleEC-3PD Cable for CT Scale

Detailed easily readable Instruction manual

18" straight mounting arm for the Innova display

· Includes three 0.0002" resolution glass scales - the MKT-42, the MKT-82, and the CT-42

· Hysteresis / Minimum Position Value

· Linear Machining Cycle (Linear Hole Positioning)

1. Does the DRO have Linear Error Compensation?

2. Is the resolution 0.0002" or better?

3. Are the scales true Glass Scales?

4. Do the scales have armored metal cables?

5. Are the displays Machine Specific?

7. Is the warranty honored and serviced by the seller?

1. Linear Error Compensation. All DRO PROS displays automatically utilize Linear Error Compensation. Not all manufacturers do, and the result is less accuracy and repeatability.

2. Scale Resolution. DRO PROS scale resolution is 0.0002". Some other manufacturers scales are rated at only 0.0005", meaning that some scales yield less than half the accuracy of our scales!

3. Glass Scales. At DRO PROS all we sell are five bearing, glass encoding scales. Some other manufacturers sell rack and pinion scales, which are not nearly as accurate and are more susceptible to contamination and damage.

4. Armored Metal Cables. All DRO PROS scale cables are completely protected by an armored metal sheath. Other manufacturers simply use plastic tubing, which can easily be cut or damaged, especially when working around a mill or lathe!

5. Machine Specific Display. DRO PROS displays are engineered specifically for the application. For example, the INNOVA 20iM milling machine display is a completely different design than the INNOVA 20iT lathe display.

7. Warranty. All warranty issues are handled in the USA, not an overseas third party!

FAGOR Innova 30i-M three axis Milling Machine Display:

INNOVA 30i-M Basic and Special Functions Explained:

Inch/Metric Display - Allows the operator to choose between inch and metric display. Resolution is .0002" or .005mm.

Enter Dimensions - Allows operator to manually input desired dimension / coordinate.

Fine / Coarse Resolution - Turns off the last decimal digit (coarse resolution) in which fine resolution is excessive.

Hysteresis / Minimum Position Value - When drilling in hard materials, this function prevents the display from fluctuating rapidly - enabling this function temporarily eliminates this oscillation.

Center Find Function - Automatically calculates the center of the workpiece after the edges are located.

ABS/INC Coordinate Display Switch - Allows the operator to switch between absolute and incremental display. 'Absolute' display references the work piece zero coordinate you designate. You may choose the absolute center point of your workpiece or perhaps a corner of your workpiece, the decision is yours. Incremental display references any arbitrary coordinate/position without losing your designated zero point. For example, to locate a point exactly in the middle of your workpiece you would most likely use 'absolute' display to locate the point. To locate points exactly .78 distant from an arbitrary point somewhere in the middle of your workpiece, you would then switch to 'incremental' display, designate the present position as a zero point, and then simply move your workpiece until .78 was displayed.

Built In Calculator - The display includes a built in calculator function which provides normal mathematical functions such as: add, subtract, multiply, divide, sin, cosine, tangent, etc.

20 Reference Datum Points - In many batch machining operations, the operator has to switch between 'absolute' and 'incremental' displays many times, which is not convenient and can potentially lead to mistakes. The 20 Reference Datum Points feature allows the operator to designate up to 20 separate data points, which greatly simplifies machining of repetitive parts.

Power off memory - This function allows the operator to store the work piece zero position in memory. If the machine is turned off at night or there is a power failure, the zero reference points can be recovered without having to reestablish the work piece zero point.

Linear Machining Cycle (Linear Hole Positioning) - Provides a linear hole positioning function for drilling holes a fixed distance apart, at any angle.

Bolt Hole Drilling - Allows the operator to drill holes in a circle from a designated center point.

Radius / Diameter - When measuring radii or diameter, enables the operator to display twice the real displacement.

Automatic Angle Calculation - Automatically calculates part angle after the tool is touched twice to the side of the workpiece. Also allows the operator to accurately position the workpiece at an angle on the work table.

Corner Rounding - Enables the operator to machine round corners or arc surfaces, as often encountered in mold making.

Tool Radius Compensation - Allows the operator to automatically compensate for a tools diameter while machining.

Shrinkage Calculation - For mold making, allows the operator to enter a shrink factor to compensate for material shrinkage during cooling.

Easy Setup Mode - Enables access to special functions, such as swapping or 'reversing' the direction a scale reads.

Machine Error Compensation - Common to all of Fagor's displays, provides improved display accuracy.

Lifetime Warranty on Glass Scales: All FAGOR glass carries a lifetime warranty. All other FAGOR digital readout components are protected by a 3 year warranty. All warranty claims are handled directly by FAGOR.

or need some help? Let us take care of it with a toll-free call to California!

Call us now TOLL FREE within the United States at 1-(***)-628-6028!

DRO PROS - Digital Readouts at affordable prices!