Please note that you can download the ACTUAL program used to browse this particular CD (it'll automatically start when you insert this CD into your CD-ROM drive):

MACHINE SHOP AND TOOLS TRAINING/REFERENCE MANUALS

consisting of 13 training manuals/subcourses – 2330 pages of self-study material with diagrams and illustrations (you can preview some of the manuals/courses below).

This CD is created and produced by planet-e-tech from non-copyrighted, public domain, declassified or non-classified US Government documents, and is designed to work under Windows operating system (the .pdf files are also viewable under other platforms, but some automatic features are likely to be disabled).

All the manuals on this CD are in Adobe Acrobat (.pdf) format, and the latest version of Adobe Acrobat Reader is also included on this CD for your convenience.

Your satisfaction is our priority!

1. FUNDAMENTALS OF MACHINE TOOLS (310 pp)

Preview several pages from this manual (click here): 80 Kb

2. TOOLS AND THEIR USES (368 pp)

3. USE AND CARE OF HANDTOOLS AND MEASURING TOOLS (277 pp)

4. BANDSAW OPERATIONS (96 pp)

5. MILLING MACHINE OPERATIONS (81 pp)

Preview several pages from this manual (click here): 270 Kb

6. LATHE OPERATIONS (140 pp)

7. METAL BODY REPAIR (108 pp)

8. CONSTRUCTION PRINT READING (500 pp)

9. PRINCIPLES OF DRAFTING AND SHOP DRAWINGS (117 pp)

10. MACHINE SHOP CALCULATION (110 pp)

11. PRECISION MEASURING AND GAGING (93 pp)

12. METAL PROPERTIES, CHARACTERISTICS, USES, AND CODES (55 pp)

13. NONDESTRUCTIVE TESTING (75 pp)

The purpose of this training circular is to provide a better understanding of power-driven

machine tools. One of the main objectives is for this publication is to be clear and understandable.

Illustrations throughout this publication show the step-by-step process of many machine shop operations.

The tables, charts, formulas, weights, and measurements in this publication can be a ready reference for

selecting the proper tooling and math formulas for machining different materials.

q CHAPTER 1. Introduction to the Machine Shop

q CHAPTER 2. Properties, Identification, and Heat Treatment of Metals

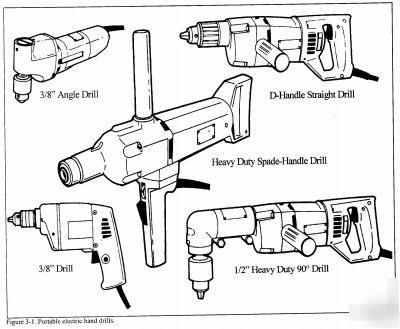

q CHAPTER 3. Portable Machine Tools

q CHAPTER 4. Drilling Machines

q CHAPTER 5. Grinding Machines

q CHAPTER 8. Milling Operations

q CHAPTER 9. Milling-Grinding-Drilling and Slotting Attachment (Versa-Mil)

q APPENDIX B. Weights and Measures

This manual provides information on the use and care of selected hand tools and measuring

tools. It will explain the types and uses of a large number of tools, a practical application of a selected

group of tools, safety requirements, general care, and limited repair. A user must have, choose, and use the

correct tools in order to do the work quickly, accurately, and safely. Without the proper tools and

knowledge of how to use them, the user wastes time, reduces efficiency, and may face injury.

§ Miscellaneous measuring tools

§ Surface, depth, and height gages

§ Ring and snap gages and gage blocks

§ Miscellaneous measuring gages

§ Grinders and sharpening stones

§ Pipe cutting and threading tools

§ Tube cutting and flaring tools

USE AND CARE OF HANDTOOLS AND MEASURING TOOLS

The purpose of this subcourse is to increase the mechanic’s knowledge of the use and care of

handtools and measuring tools.

q Lesson 1: SAFETY PROCEDURES FOR USING HANDTOOLS AND POWER TOOLS

o Task 1: Describe the safety procedures for using handtools and power tools

q Lesson 2: USE AND CARE OF HANDTOOLS

o Task 1: Describe the procedures for the use and care of non-edged handtools

o Task 2: Describe the procedures for the use and care of edged handtools

q Lesson 3: USE AND CARE OF MEASURING TOOLS

o Task 1: Describe the procedures for the use and care of measuring tools

The purpose of this subcourse is to introduce the use of the bandsaw machine and to describe

the methods used in maintaining and troubleshooting this machine for possible problems or malfunctions.

q Lesson 1: Uses of the Bandsaw

o Task 1: Describe the use of the bandsaw machine

q Lesson 2: Bandsaw Maintenance and Troubleshooting

o Task 1: Describe the methods used to repair and adjust the bandsaw

o Task 2: Describe the procedures for troubleshooting the bandsaw

The purpose of this subcourse is to introduce the student to the setup, operations and

adjustments of the milling machine, which includes a discussion of the types of cutters used to perform

various types of milling operations.

q Lesson 1: Milling Machine Operations

o Task 1: Describe the setup, operation,and adjustment of the milling machine

o Task 2: Describe the types, nomenclature, and use of milling cutters

The purpose of this subcourse is to introduce the uses of the lathe, to include safety; the uses,

repair and adjustment of lathe attachments; and the various thread forms, uses, calculations and machining

q Lesson 1: The Lathe Uses and Safety; Uses, Repair, and Adjustment of Lathe Attachments; and Various Thread Forms, Uses, Calculations, and Machining Techniques

o Task 1: Describe the uses of the lathe, to include safety.

o Task 2: Describe the uses, repair, and adjustment of lathe attachments.

o Task 3: Describe the various thread forms, uses, calculations, and machining techniques.

The purpose of this subcourse is to introduce various operations required to repair damaged

vehicles and specifically describe the repair procedures required for proper glass, radiator, and fuel tank

q Lesson 1: Operations Required To Repair Damaged Vehicles And Components;

o Task 1: Describe the operations required to repair damaged vehicles and components.

q Lesson 2: Operations Required For Glass, Radiator, And Fuel Tank Repair;

o Task 1: Describe the operations required for proper glass repair.

o Task 2: Describe the operations required for proper radiator repair.

o Task 3: Describe the operations required for proper fuel tank repair.

Construction print reading is a key skill for technical students. Fortunately, a formal

education is not essential for achieving proficiency in this important subject; the study of correspondence

courses such as this can provide the essential skills.

q Lesson 1: Principles and Methods

q Lesson 2: Architectural Drawings

q Lesson 3: Utilities Drawings

q Lesson 4: Heating, Air-Conditioning, and Refrigeration Drawings

q Lesson 5: Bills of Materials

q Appendix B: Conversion Tables

q Appendix C: Extract TM 5-704

PRINCIPLES OF DRAFTING AND SHOP DRAWINGS

This subcourse is designed to introduce the student to the principles of drafting and shop

drawings. It describes the primary types of mechanical drawings used for shop drawings. It endeavors to

teach the students how to read shop drawings through visual identification of lines, symbols, etc.

q Lesson 1: Drafting And Shop Drawing Fundamentals

o Task 1: Describe orthographic projection theory and freehand drafting

o Task 2: Describe drafting instruments and the fundamentals of geometric construction

o Task 3: Describe the theory and fundamentals of pictorial drawings: oblique and isometric projection

o Task 5: Interpret a shop drawing

The purpose of this subcourse is to introduce various mathematical calculations involved in

the machine shop operations of a maintenance company organization in the field. The scope of the

subcourse serves to introduce the methods and procedures for solving problems involving addition,

subtraction, multiplication, and division of fractions and decimals, and conversion of fractions to decimals

and decimals to fractions; conversion of linear measurements from the English to the metric system and

vice-versa; and for solving problems using ratio, proportion, and trigonometry.

q Lesson 1: Addition, Subtraction, Multiplication, And Division Of Fractions And Decimals; And Conversion Of Fractions To Decimals And Decimals To Fractions

o Task 1: Describe the processes for adding, subtracting, multiplying, and dividing fractions

o Task 2: Describe the processes for converting fractions to decimals and decimals to fractions; and for adding, subtracting, multiplying, and dividing decimals

q Lesson 2: Conversion Of Linear Measurements From The English To The Metric System And From The Metric To The English System; And Solving Problems Using Ratio, Proportion, And Trigonometry

o Task 1: Describe the processes for converting linear measurements from the English to the metric system and from the metric to the English system

o Task 2: Describe the processes for solving problems using ratio and proportion

o Task 3: Describe the processes for solving problems using trigonometry

PRECISION MEASURING AND GAGING

The purpose of this subcourse is to introduce various operations required to repair damaged

vehicles and specifically describe the repair procedures required for proper glass, radiator, and fuel tank

Lesson 1: Precision Gages And Measuring Tools, And Types of Fits, Tolerances, And Allowances

Task 1: Describe the different types of fits, tolerances, and allowances used in the machinist trades.

Task 2: Describe the proper use and care of precision gages and measuring tools.

METAL PROPERTIES, CHARACTERISTICS, USES, AND CODES

The purpose of this subcourse is to introduce the student to the properties of metals, their

characteristics, uses and identification codes.

q Lesson 1: THE PHYSICAL AND MECHANICAL PROPERTIES OF VARIOUS METALS, AND USE OF THE HARDNESS TESTER, CHEMICAL ANALYSIS, AND BENCH GRINDER TO IDENTIFY VARIOUS METALS;

o Task 1: Describe the processes for identifying the physical and mechanical properties of various metals;

o Task 2: Describe the processes for using the hardness tester, chemical analysis, and bench grinder to identify various metals.

This subcourse is designed to familiarize you with nondestructive testing.

q Lesson 1: Fluorescent Penetrant Testing

q Lesson 2: Magnetic Particle Testing

APPROVED BY U.S. GOVERNMENT FOR PUBLIC DOMAIN RELEASE… DISTRIBUTION UNLIMITED…

Please click here to see other items that we offer for sale!