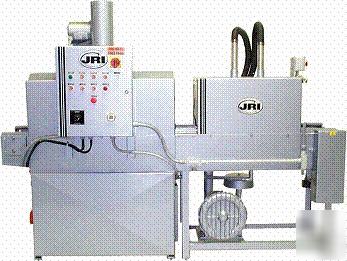

NEW MAJOR BRAND BELT WASHER - TWO STAGE - WASH & DRY-

This is a NEW unit to which you can add custom options. The continuous cleaning adds to your productive.

Model: MCC 2000 (mild steel construction)

Approximate overall dimensions: 84†long X 62†wide X 72†tall

Part opening: 24†Wide X 15†Tall

Breakdown of zones within the unit:

* 28†(2’ 4â€) spray wash zone

* 12†(1’) drip/exit from wash

* 16†(1’ 4â€) exit from wash

Conveyor belt type: 24†Wide, 1†X 1†Galvanized Steel, flat wire clinched edge

Max load of conveyor is 1,000 lbs. evenly distributed.

Drive system: Variable speed, Direct Current (DC) Operating speed is 1 to 12’/min. with current sprocket-to-sprocket ratio.

Add Blow-off Stage (Mild Steel)

Tunnel accessibility: The tunnels are equipped with removable side panels for access to the entire interior of the tunnel.

Tank accessibility: The solution tank is equipped with a large “lift-off†hatch to provide access to the tank for cleaning and/or service.

“Closed-Loop†– Re-circulating

Heat source: 36KW Electric heat

Solution capacity: 200 Gallons-Insulated

Drain: 2†Conveniently located for ease of draining.

THE FOLLOWING OPTIONS ARE INCLUDED

MCCS-1000, CONVEYORIZED CLEANING SYSTEM,

Basic conveyorized cleaning system in a mild steel configuration with wash section.

CT-800 – CHIP TRAY,…………………………………………..

The chip tray consists of a mild steel tray, which is mounted under the conveyor belt. This tray in turn diverts all of the solution to a central point in the tank access area, where it is forced to flow through an easily removable, mild steel perforated basket. After flowing through the basket, the water returns to the main tank. This option retains the majority of the sludge and particulate matter in the basket for easy removal.

SO-100 – LOW WATER SHUT OFF (MILD STEEL), …….....

The low water shut-off incorporates an adjustable, 2†diameter, stainless steel float-switch that is to be mounted at such a distance above the heater so as to protect the heater in the event of a low-water condition. In the event that a low-water condition exists, the low water shut-off will turn off the heater and/or pump circuit(s), thereby protecting the heater and pump.

* rinse cycle and many custom options available